Article by Noémi Mészáros

Along with the expansion of business and increasing complexity of purchasing, organizations are continuously facing new challenges within their procurement cycle due to the lack of keeping up with current trends in technology enhancements that drive efficiency and help retailers to be on the fast track over competitors.

Paper-driven procurement has a negative impact on an organization’s profit margin. A legacy goods sourcing process drives inefficient procurement, losing margin on delayed purchases, missed allowances, and handling disputes via voluminous paperwork and far too many back-and-forth emails needed to put things straight. There is no point of attempting to accelerate the process with obsolete tools like emails and spreadsheets.

In order to optimize your organization’s procurement system and obtain desired results while reducing cost, saving time and building advantageous supplier relationships for both parties, you need to embrace modern procurement techniques providing the latest methods and means.

Oracle Retail Merchandising System (RMS) Purchasing functionality offers among its well-known features a solution that supports management of orders issued through a diverse range of sources, including replenishment, Allocation, Advanced Inventory Planning, Store Requests or Franchise Orders.¹ In order to simplify these integration points to an extent that complete or partially complete order records from external sources could be imported and maintained with minimal configuration, the ‘PO Induction’ framework was developed.

Multiple methods are now available for uploading data directly into RMS or first into a staging area via the Retail Integration Bus (RIB) interface, via bulk load or loading manually thru spreadsheet import. The templates used by all types of PO induction are pre-programmed spreadsheets that offer flexibility in specifying the formats that retailers may wish to work with in case of mass maintenance activities and allow a higher accuracy level in data input as well as consistency in output. Each worksheet corresponds to a table in RMS. In terms of mass maintenance functionalities, other than the option for mass approval and uploading or downloading purchase order data, further updates and modifications are enabled such as changing the color or location of items or editing the cost of all items on a PO or across multiple POs.

One of the key benefits of the induction solution allows for addition of master PO number which will facilitate related orders to be clustered together for reporting, while individual POs still have a single delivery date. You can also utilize pre-issued order numbers for request and reservation.

PO Induction supports the creation of both buy plans and multi-drop delivery schedules that can form the basis of uploading order information. There is a possibility to consolidate store-level purchase records as a bulk order for optional allocation at a later point in time or you can generate a cross-docked order as well.

As part of the base product, RMS provides a template for PO Induction called Purchase Order Data. This template includes all the columns on the ordering tables that are supported for induction. Each template defined maps to a spreadsheet format wherein the tables included in the template corresponds to the worksheets in the spreadsheet, and the columns selected map to the columns in the individual worksheets. Each worksheet will carry a column titled Action Type. This field indicates the action that should be taken in the staging table and on upload to the RMS system of record tables. For certain worksheet columns, a list of valid values has been included to assist the user in selecting the correct value to update RMS. This exists for most columns where there is a predefined list of valid values in RMS, such as the Yes/No fields, Order Status, etc.

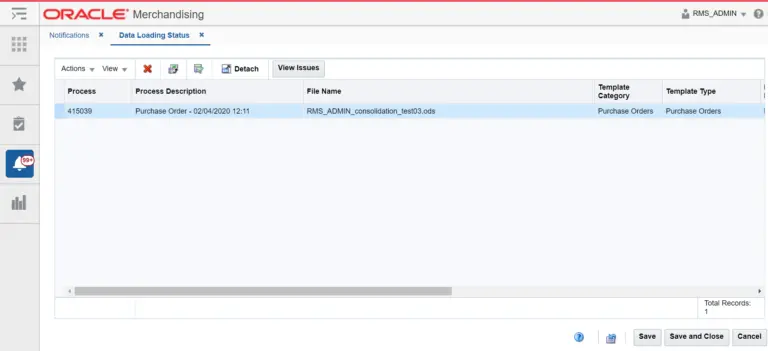

Because updating data in spreadsheets provides so much flexibility, it can also lead to errors. In terms of Error Resolution, upload or download requests that did not process successfully will have their status set to “Processed with Errors” or “Processed with Warnings”. This screen allows users to drill down to the ‘PO Induction Issues View’ screen to view the details of the errors or warnings associated with a selected upload or download request.

This screen (shown below) displays information on which worksheet had the error, which column and row in the worksheet is in error, and a short description of the issue.

The above error screen details serve as a guide for error resolution and self-correction in the original document. Once the errors have been corrected, the data can be re-uploaded into the staging area of RMS.

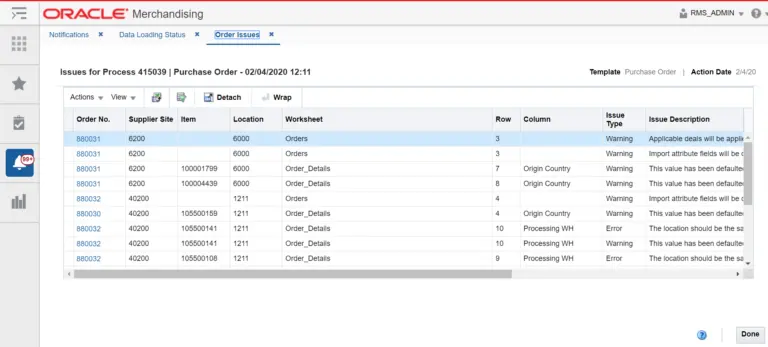

Let’s see how the creation of bulk purchase orders works:

In case of consolidation, the upload process will not create an allocation from the warehouse to the individual stores but only the consolidated order item/location records.

To create this type of order, users will need to indicate which of the store level purchase quantity lines are to be consolidated by including a processing type of “Consolidate” in the order details sent to RMS.

The upload process into the staging area will check if any of the detail rows on each order have been marked for consolidation and will also check if these have a processing warehouse specified. If a processing warehouse has not been specified for a store that has been marked for consolidation, the upload process will default the source warehouse associated with the item/location in RMS. In the event of a default warehouse not being found, the upload process will log an error and not upload those records into the staging area.

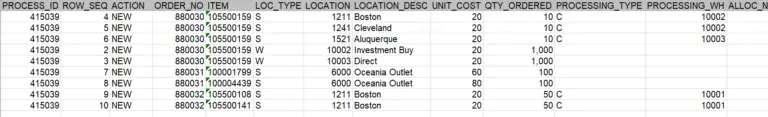

You can see here that for those items whose Processing Type is ‘Consolidation’ and where we have not specified any Processing WH for, the induction mechanism has automatically filled in the table with the associated source warehouse information (WH 10001 and 10003):

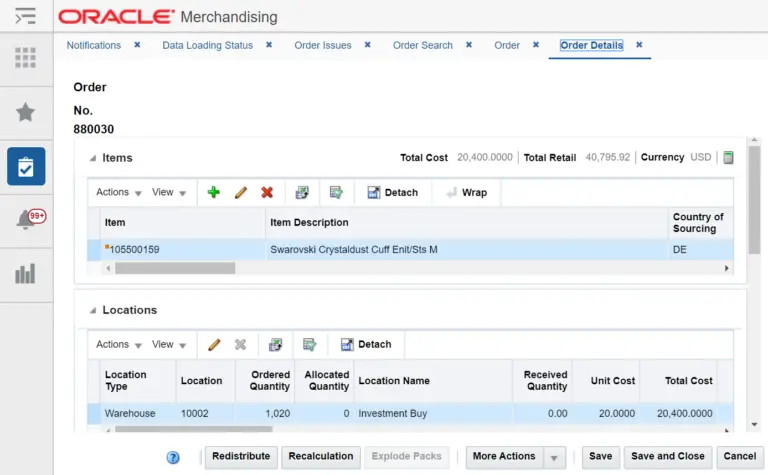

When this template is uploaded into RMS, the net order quantity is consolidated at a warehouse level.

Retailers may also choose to build out a bulk order based on the buy plan and use it to create a simple allocation. Building such cross–docked orders can be achieved by setting the Processing Type field to ‘cross dock’ for those individual locations that require cross-docking. If the spreadsheet contains an order that has one or more rows (item-locations) that are marked for cross-docking (processing type= ‘Cross dock’), then the upload process will check if all the rows marked for cross docking have a processing (cross-dock) warehouse specified.

If none is specified, the system will try to identify a default warehouse using the same logic as specified for Order Consolidation.

The upload process into RMS will roll up the need for each processing warehouse by aggregating the warehouse need together with the need for each of the cross-dock locations that the warehouse serves. Individual allocations will be created for each item that is cross-docked. When downloading cross-docked POs into a spreadsheet template for editing, each of the destinations on the allocations linked to the order will be extracted as a separate row for the spreadsheet. Similarly, the un-allocated quantity at each location on the order will be shown as a distinct row on the spreadsheet.

Speaking of downloading purchase order data, the PO Induction framework supports the downloading of orders from either the staging area or RMS to a spreadsheet. Using this functionality makes your life easier for a number of reasons, either you want to download data from RMS for reporting purposes or to communicate with other parties or systems or to simply complete/add details to order data that has been loaded into the staging area from an external system.

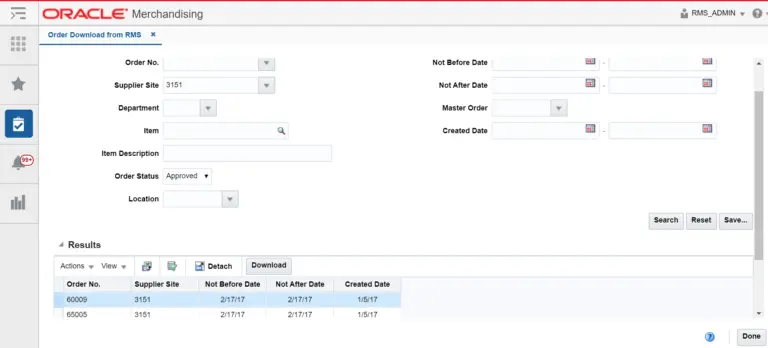

You can access the Order Download screen from the RMS menu under the Ordering folder and by specifying one or more elements of your filtering for any order:

Download requests require the specification of a template type, and the name and location under which the file generated should be saved.

¹¹¹The downloaded order information is formatted in the same template structure as when uploading data to RMS and the default action being offered by the PO induction is the ‘update’ functionality permitting to manually modify existing POs. The updated data can be re-uploaded to RMS as long as it contains the minimal data set required for order creation.

I hope this brief introduction to RMS Purchase Order induction capabilities is useful and helps our clients and retailers around the globe implement more efficient processes to help their business perform better. To contact Quickborn and speak with our team of experts, please contact us here.

References:

¹ Oracle® Retail Merchandising System PO Induction Overview White Paper Release 15.0